Application of carbon fiber in semiconductor precision equipment

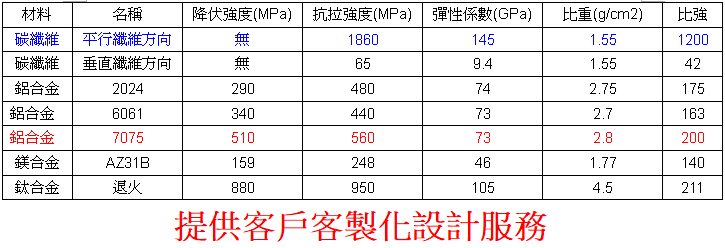

High-performance carbon fiber component solutions specifically designed for semiconductor manufacturingAs semiconductor manufacturing processes move toward nanometer levels, machine automation and high-speed development, “carbon fiber composite materials” are gradually replacing traditional metal materials with their high rigidity, low thermal expansion, high chemical resistance and lightweight properties, becoming an ideal choice for key components in advanced process equipment.Chen Hsuan Technology is deeply engaged in the development of precision structural materials, providing customized carbon fiber solutions, which have been successfully applied to Mask transmission system, wafer clamping fixture, laser processing platform, AOI automation module, robot arm connecting rod, clean room structural parts and other high-demand fields.Why choose carbon fiber for semiconductor devices?🌡 Ultra-low coefficient of thermal expansion (CTE)Even in an environment with rapid changes in high and low temperatures, carbon fiber can still maintain geometric stability, reduce the risk of thermal deformation, and ensure long-term and high-precision operation of precision equipment.🪶 Extremely light weightIt is lighter and more rigid than aluminum alloy, which greatly reduces the moving mass and energy consumption of equipment and improves servo control accuracy and production speed.🧪 High chemical resistance and cleanlinessCarbon fiber has excellent resistance to acidic and alkaline gases and volatile substances, and can be further matched with anti-static or corrosion-resistant coating on the surface, making it suitable for Class 10~1000 clean room environments.🛠Customized processing flexibilityIt can be designed into hollow beams, honeycomb structures, special-shaped panels, thin-walled panels or precision fixture frames according to application requirements, and supports CNC, vacuum molding, hot pressing, laser processing and metal composite bonding.Technology Development Focus|Core Competencies of Chenxuan Technology1. Material structure simulation and mechanical analysis

From material selection, structural recommendations, sample proofing to formal mass production, all are provided by the internal team. One-stop service helps you significantly shorten the development cycle and ensure the feasibility of the design.✅ Provide 2D/3D drawing design and simulation analysis

✅ Small quantity and variety fast proofing support

✅ Cooperate with automation integration and develop simultaneously with module factories

✅ Can be combined with metal, ceramic, quartz and other materials to make composite structural partsChen Hsien Technology, your reliable partner in high-end carbon fiber manufacturing

- Use FEM/CAE simulation analysis to estimate thermal expansion, stiffness and resonance frequency

- Assist customers to optimize their designs: achieve the lightest structure, maximum rigidity ratio, and minimum deformation

- Choose high modulus (HM), high strength (HS) or medium modulus carbon fiber cloth according to the function of the part

- Customized winding direction and interlayer angle (such as 0/45/90/135 degrees) to meet anisotropy control

- Adopt vacuum high temperature pressing, CNC five-axis machining, laser drilling and metal parts composite bonding technology

- The finished product size tolerance can be controlled within ±0.02 mm

- Applicable products such as: frames, support plates, adsorption arms, guide beams, low-temperature optical platforms, etc.

- Full dimensional accuracy inspection (using 3D and laser interferometer)

- Non-destructive inspection of fiber structure (Ultrasound/IR)

Thermal Cycle Stability Test (-40°C ~ +150°C) - Weight and density tracking and control

- Cleanroom grade cleaning and packaging

From material selection, structural recommendations, sample proofing to formal mass production, all are provided by the internal team. One-stop service helps you significantly shorten the development cycle and ensure the feasibility of the design.✅ Provide 2D/3D drawing design and simulation analysis

✅ Small quantity and variety fast proofing support

✅ Cooperate with automation integration and develop simultaneously with module factories

✅ Can be combined with metal, ceramic, quartz and other materials to make composite structural partsChen Hsien Technology, your reliable partner in high-end carbon fiber manufacturing

- More than 10 years of experience in developing professional carbon fiber parts

- Taiwan’s own factory, fully automated process, stable delivery

- Serving many semiconductor equipment manufacturers, packaging plants and optoelectronic system integrators

- International quality standards verified, competitive mass production capabilities

- Our technical team can work with you to solve process challenges and innovation needs

Composite materials can be processed and manufactured according to customer needs

Professional quartz processing

High-precision solutions for optical inspection and semiconductor processing

In high-precision industries such as optical inspection systems and semiconductor process equipment, “quartz glass” is widely used in key components due to its excellent optical transmittance, thermal stability and chemical inertness. Chenxuan Technology focuses on high-precision quartz processing services and has complete equipment and process capabilities. It provides customers with one-stop solutions from drawing design, material selection, precision processing to strict testing, helping major technology equipment manufacturers to achieve high-quality and high-stability quartz parts needs.Why choose Chenxuan Technology’s professional quartz processing?✅ High-purity quartz material supply chain integration

✅ Professional CNC quartz processing technology and module integration capabilities

✅ Cleanroom and high temperature process requirements

✅ Customized production, small quantities and large quantities can be delivered quickly

✅ Serving many semiconductor, optoelectronics and equipment manufacturersQuartz Processing Technology Focus | Our Core Advantages🔬 High-precision cutting and grinding technology

Quality Assurance and Inspection Mechanism

✅ Professional CNC quartz processing technology and module integration capabilities

✅ Cleanroom and high temperature process requirements

✅ Customized production, small quantities and large quantities can be delivered quickly

✅ Serving many semiconductor, optoelectronics and equipment manufacturersQuartz Processing Technology Focus | Our Core Advantages🔬 High-precision cutting and grinding technology

- Adopt high-end CNC quartz machining center with accuracy up to ±0.01 mm

- Provides a variety of thicknesses and surface treatments, supporting complex designs such as special shapes, slots, chamfers, etc

- Quartz material can withstand high temperatures of over 1000°C and is suitable for vacuum, atmosphere furnaces, and laser processing equipment

- The thermal expansion coefficient is extremely low, ensuring that the structure is stable and does not deform in high temperature environments

- High optical transmittance (UV and IR transmittance can reach over 90%)

- Resistant to acid, alkali and plasma corrosion, suitable for etching, CVD, PVD and other processes

- Complete cleanroom cleaning process to ensure products meet Class 100 standards

- Each quartz piece is ion cleaned and dust-free packaged, suitable for direct use in the machine

| Application Areas | Quartz Parts Example |

| Semiconductor process equipment | Quartz boat, quartz tube, wafer carrier, annular heating hood |

| Optical/Laser Inspection Equipment | Light-transmitting window, quartz platform, optical mirror stand, sample piece |

| Chemical Vapor Deposition (CVD) | Quartz reaction tank, gas distribution pipe, diffusion tube |

| Vacuum equipment/dry etching system | Vacuum window, insulating stage, light guide, reflector frame |

We are well aware that quartz components must have high stability and consistency in high-end equipment, so we have established the following quality mechanisms:🔍 Full size/appearance inspection (including high-precision measuring tools and microscopic inspection)

📏 Thickness uniformity and flatness inspection

🔬 Optical transmittance detection (provide corresponding detection for UV/IR requirements)

💧 Ion residual test and cleanliness confirmation

📦 Vacuum clean packaging to ensure delivery qualityCustomized Quartz Processing Capabilities | Design and TechnologyChen Hsien Technology provides complete customized quartz processing solutions, including:

📏 Thickness uniformity and flatness inspection

🔬 Optical transmittance detection (provide corresponding detection for UV/IR requirements)

💧 Ion residual test and cleanliness confirmation

📦 Vacuum clean packaging to ensure delivery qualityCustomized Quartz Processing Capabilities | Design and TechnologyChen Hsien Technology provides complete customized quartz processing solutions, including:

- Quickly proofing according to customer 3D drawings/2D engineering drawings

- The engineering team can provide design optimization suggestions to improve durability and processability

- Can support special coating treatment, metal parts integration, and heterogeneous material joining modules

- Small quantity/variety/fast mold opening can all be supported to accelerate product development cycle

- ✅ With more than 10 years of quartz processing experience and professional team

- ✅ Produced in Taiwan, stable delivery and quality control

- ✅Cooperate with high-precision industries such as semiconductors, optoelectronics, lasers, biomedicine, and testing

- ✅ Our clients include many internationally renowned semiconductor equipment manufacturers

- ✅ Provide complete solutions from design consultation to mass production

CHT-DV65-24025-R2 Dimming Controller User Manual

Quartz Rod

Quartz round plate

Quartz ring

Professional ceramic processing

High-precision solutions for semiconductor and optical inspection equipment

In high-end precision industries, such as semiconductor process equipment, optical inspection systems and laser equipment, high-performance ceramic materials (such as aluminum oxide, aluminum nitride, silicon nitride) have become indispensable materials for key components due to their excellent high temperature resistance, insulation, chemical resistance and structural stability.Chen Hsien Technology has many years of experience in precision ceramic parts processing. Combining its own technology with automated processing equipment, it provides customized ceramic product design and manufacturing, and has successfully assisted many leading semiconductor and optoelectronic equipment brands in optimizing process quality and equipment stability.Why choose Chen Hsien Technology’s ceramic processing services?🔹 Specializes in precision ceramic molding and processing

🔹 Fast delivery of small quantities of diverse and high-strength customized products

🔹 Experience in application of high insulation, high hardness and high stability ceramic materials

🔹 Quality tracking and complete testing process, all made in TaiwanTechnology Development Focus|Optimizing Processing Capabilities for Precision Ceramic Parts💡 High Strength Ceramic Material Application

Quality Assurance Mechanism|Zero-defect manufacturing standards🧩 Full-process ISO-level production control

🔍 Full inspection of size, shape, flatness and concentricity

📏 High-precision CMM and optical measuring equipment introduced

🧼 Ion residue and particle cleanliness inspection to meet dust-free requirements

📦 Shockproof packaging and airtight packaging to ensure delivery qualityCustomized process integration | One-stop service from design to deliveryWe understand the changing needs of customers for materials and designs when developing new equipment and processes, so we provide:

🔹 Fast delivery of small quantities of diverse and high-strength customized products

🔹 Experience in application of high insulation, high hardness and high stability ceramic materials

🔹 Quality tracking and complete testing process, all made in TaiwanTechnology Development Focus|Optimizing Processing Capabilities for Precision Ceramic Parts💡 High Strength Ceramic Material Application

- Using high-purity aluminum oxide (Al₂O₃), aluminum nitride (AlN), silicon nitride (Si₃N₄) and other materials

- Applicable to high temperature, high pressure and strong corrosion process environment

- High-precision grinding and laser cutting, the dimensional tolerance can be controlled within ±0.01 mm

- Surface roughness (Ra) can reach nanometer level, meeting high-precision assembly requirements

- The material has excellent acid and alkali resistance and plasma etching tolerance

- Supports dust-free processing and ultrasonic cleaning, suitable for Class 100 equipment applications

- Can be made according to drawings or 3D files, customized holes, threads, grooves, curved surface structures

- Can integrate metal-ceramic composite parts, support composite processing and dissimilar material joining

| Application device type | Ceramic parts examples |

| Semiconductor process equipment | Insulation carrier, ion etching chamber lining, ceramic nozzle, wafer clamp |

| Optical and laser inspection systems | Ceramic bracket, light-transmitting hole, optical platform fixing seat |

| CVD/PVD process chamber | Gas guide plates, ceramic washers, plasma reaction chamber insulation rings |

| Vacuum system and robotic arm | Ceramic slide rails, insulated terminals, sealing components, precision sleeves |

🔍 Full inspection of size, shape, flatness and concentricity

📏 High-precision CMM and optical measuring equipment introduced

🧼 Ion residue and particle cleanliness inspection to meet dust-free requirements

📦 Shockproof packaging and airtight packaging to ensure delivery qualityCustomized process integration | One-stop service from design to deliveryWe understand the changing needs of customers for materials and designs when developing new equipment and processes, so we provide:

- Customized design suggestions and material selection support

- Trial production/small sample flexible production process

- One-on-one technical communication and image modification support from engineers

- Made in Taiwan, shorten delivery time and quickly respond to customer modification requests

Microporous ceramic suction cup

Ceramic Robot Arm

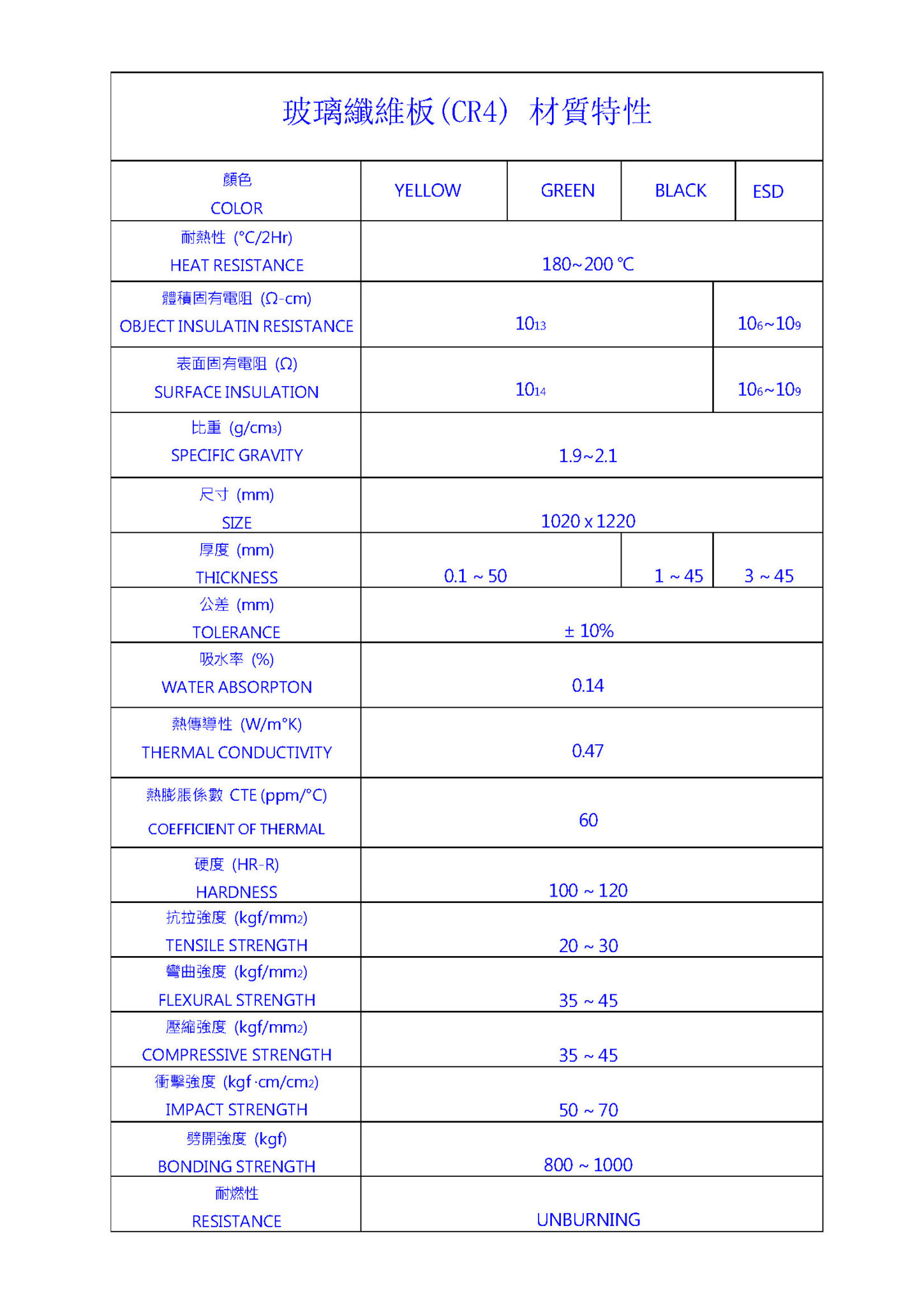

Professional fiberglass board processing

High thermal insulation and low thermal expansion characteristics to create high reliability precision equipment solutions

In high-precision industries such as semiconductor process equipment, optical inspection instruments and automated control systems, the thermal stability and mechanical strength of materials directly affect the stability and life of equipment operation. Glass Fiber Reinforced Plastic (GFRP) has become an indispensable structural or thermal insulation component in precision equipment due to its excellent thermal insulation ability, insulation, mechanical strength and low thermal expansion coefficient.Chen Hsien Technology has been deeply engaged in the precision processing services of fiberglass boards for many years. We have built our own automated processing production line in Taiwan, providing customized size, shape and functional structure design and production, which are widely used in major well-known equipment manufacturers at home and abroad.💡 Key Benefits Overview✅ High thermal insulation, suitable for high temperature equipment application scenarios

✅ Low thermal expansion coefficient to avoid equipment displacement and error

✅ High strength and insulation to ensure electrical and structural safety

✅ Small quantity, variety and precision hole customization design support

✅ Full process quality control to ensure stable supply of mass production needsTechnology Development Focus | Advantages of Fiberglass Board in Precision Equipment🔥 Excellent thermal insulation performanceFiberglass board has excellent thermal insulation ability and can effectively block high temperature conduction during the process. It is suitable for:

🧪 Full-process dimensional and geometric inspection (using CMM, laser measuring instrument)

🧼 Surface cleanliness and dust removal, in line with clean room requirements

📦 Anti-scratch and airtight packaging to ensure delivery safety and integrity

📑 Material certificates, test reports and traceability records can be providedApplication performance range|The industry’s trusted material partner

Customized service process | Create your own fiberglass solution

📈 High customization flexibility | Small quantity, diverse quantity, fast delivery

🧪 Strict quality control system | All product inspection reports are traceable

🧩 Technical team support|Help customers shorten development time

✅ Low thermal expansion coefficient to avoid equipment displacement and error

✅ High strength and insulation to ensure electrical and structural safety

✅ Small quantity, variety and precision hole customization design support

✅ Full process quality control to ensure stable supply of mass production needsTechnology Development Focus | Advantages of Fiberglass Board in Precision Equipment🔥 Excellent thermal insulation performanceFiberglass board has excellent thermal insulation ability and can effectively block high temperature conduction during the process. It is suitable for:

- Semiconductor packaging/etching/sintering equipment

- Laser processing equipment hot zone separation

- Optical lens holder and heat source isolation structure

- Precision alignment error risk

- Displacement and loosening problems caused by high temperature and hot and cold cycles

- High-precision hole, countersink and groove design

- CNC milling, laser cutting, molding structure processing

- Double-sided grinding and surface polishing

- Multi-layer stacked fiberglass insulation module

- Structural support and insulation dual-function composite parts

- High heat-resistant fiberglass frame and fixing base

🧪 Full-process dimensional and geometric inspection (using CMM, laser measuring instrument)

🧼 Surface cleanliness and dust removal, in line with clean room requirements

📦 Anti-scratch and airtight packaging to ensure delivery safety and integrity

📑 Material certificates, test reports and traceability records can be providedApplication performance range|The industry’s trusted material partner

| Application device type | Application examples of fiberglass board |

| Semiconductor process equipment | Insulation and heat insulation board, hot zone blocking structure, wafer fixing base plate |

| Optical inspection system | Precision support structure, optical module thermal insulation protection parts |

| Laser processing equipment | High temperature reflection zone partition, laser module structure base |

| Automated handling mechanism | Insulated slide rail, positioning base, mechanism support plate |

- Demand communication: drawings or sketches are acceptable, supporting 2D/3D design files

- Engineering assessment: material recommendations, structural feasibility, thermal performance assessment

- Sample production and optimization suggestions: support sample making and quick correction

- Stable mass production and fast delivery: full-process production and packaging and shipment in our own factory

📈 High customization flexibility | Small quantity, diverse quantity, fast delivery

🧪 Strict quality control system | All product inspection reports are traceable

🧩 Technical team support|Help customers shorten development time

Fiberglass Board

Dispensing needle

Dispensing needle consumables cover a variety of materials and specifications to meet different dispensing needs.

Dimensions: Needle length: 13 mm, needle diameter: 1.49 mm, needle taper: 30 degrees, needle tip: 0.20 mmDimensions: Needle length: 13 mm, needle diameter: 1.49 mm, needle taper: 30 degrees, needle tip: 0.25 mmthimble

Dimensions: Needle length: 17 mm, needle diameter: 0.7 mm, needle taper: 10 degrees, needle tip: 22 um