⚙️ Load Cell Application Technology | High Precision × High Integration × High Reliability Sensing Solutions

🧠 Load Cell Integration Expertise by CHT Technology

With over 15 years of experience in precision mechanical design and sensor module development, CHT Technology specializes in delivering complete Load Cell solutions for diverse industrial applications. We have successfully served more than 100 enterprise clients across industries such as semiconductor equipment, factory automation, biomedical devices, food packaging, electronic assembly, and checkweighing systems.

We provide not only standard Load Cells, but also customized force sensing modules tailored to your application environments. Our capabilities include:

Structural machining

Signal processing

System-level assembly

Automation mechanism integration

We offer a full-service, end-to-end solution from components → modules → complete systems.

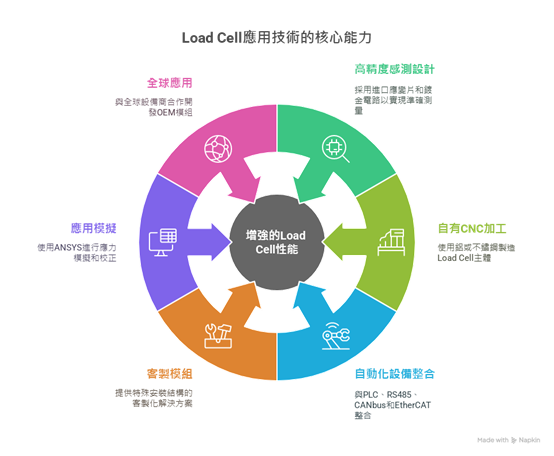

🔧 Our Core Technologies and Service Highlights

| Core Capability | Technical Description |

|---|---|

| 📐 High-Precision Sensing Design | Utilizes imported strain gauges and gold-plated circuitry to achieve ±0.03% F.S. accuracy and stability. |

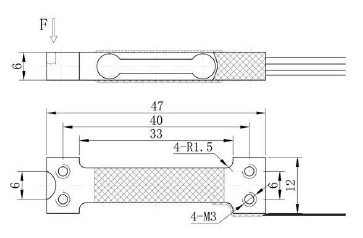

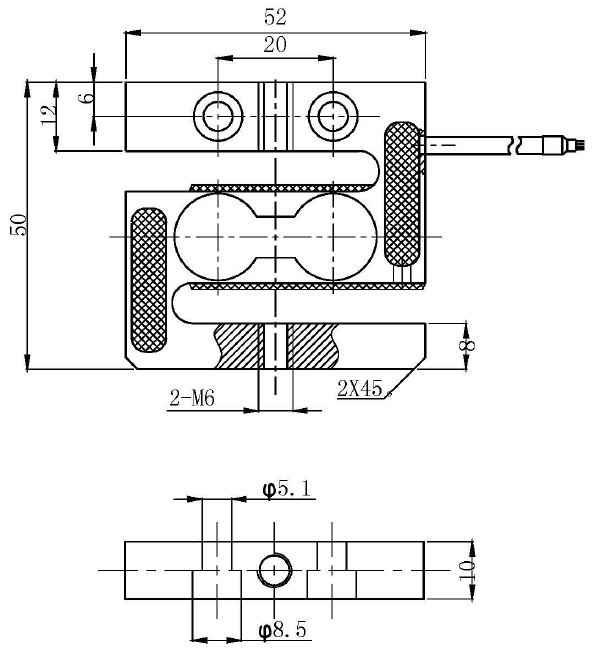

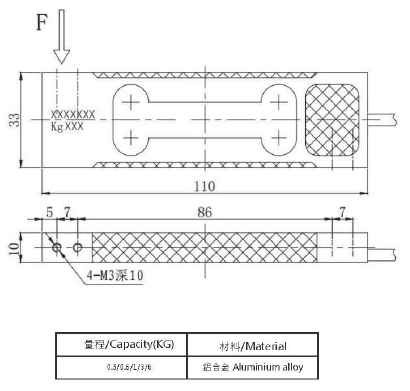

| 🛠 In-House CNC Machining & Mechanical Design | Self-manufactured Load Cell housings (aluminum/stainless steel), supporting IP65 to IP68 protection levels. |

| ⚙️ Automation System Integration | Compatible with PLC, RS485, CANbus, EtherCAT industrial communication protocols. |

| 🧩 Custom Modules & Mechanical Parts | Supports special mounting structures, high-temperature resistance, corrosion resistance, and bidirectional tension/compression sensing. |

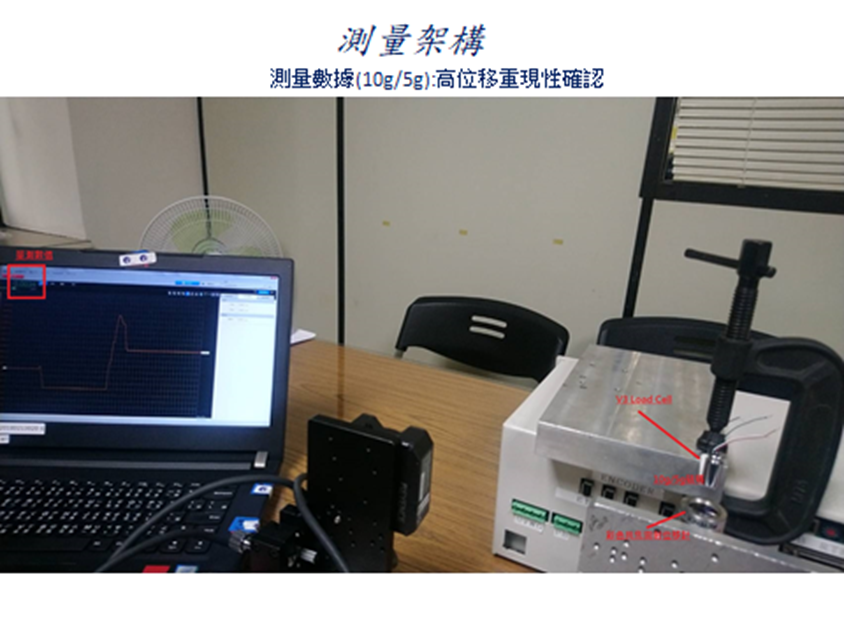

| 🔬 Application Simulation & Validation | Provides ANSYS stress analysis, calibration reports, and measurement curve analysis. |

| 🌍 Global-Level OEM Experience | Co-developed measurement modules with leading manufacturers in Japan, USA, and Germany. |

🔎 Typical Load Cell Applications

Force Monitoring in Automation Equipment

Semiconductor/optical device bonding, precision press control systems.

Weighing and Checkweighing Systems

Dynamic conveyor-based packaging and weight inspection solutions.

Mechanical Force Testing

Material testing machines and fatigue testing systems.

Tension Control in Industrial Processes

Reel tension monitoring and wire tension sensing applications.

Medical and Biotech Devices

Surgical robot force control, pressure-sensitive reaction platforms.

Smart Agriculture and IoT Sensing Systems

Load-cell-based feeding control and environmental force monitoring.

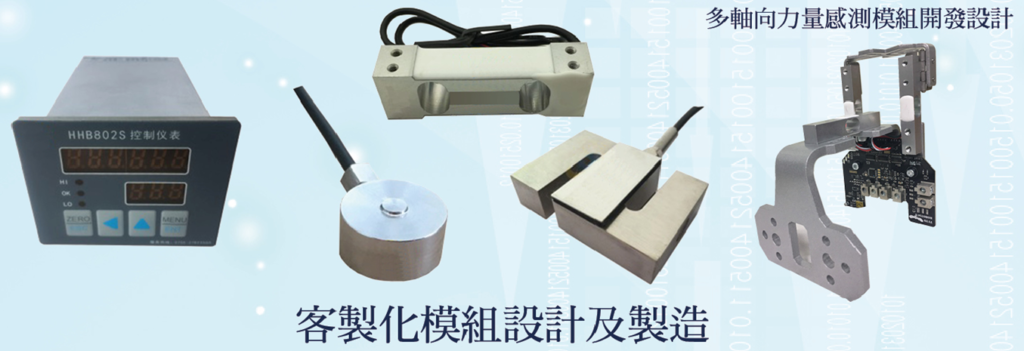

🧩 Custom Load Cell Development Services

CHT Technology offers complete customization for your application needs:

Force Range Customization: From milli-Newton (mN) up to multi-ton designs.

Output Specification Matching: Analog, 4–20 mA, RS485, Modbus, CANopen.

Form Factor Design: Miniature, low-profile, flange-type, hollow-shaft load cells.

Special Requirements Support: Explosion-proof, waterproof, high-temperature (>150 °C), and low-magnetic interference solutions.

We also provide complete signal conditioning boards (amplifiers, filters, AD converters) and support integration with client systems via LabVIEW, C++, or Python.

🏆 Global Clients and Proven Track Record

CHT Technology’s Load Cell solutions are trusted by clients worldwide:

🇯🇵 Japan – Precision packaging & printing machine maker (tension detection module).

🇩🇪 Germany – Medical equipment company (implantable micro Load Cell applications).

🇺🇸 USA – Semiconductor equipment manufacturer (AOI force calibration modules).

🇹🇼 Taiwan – Leading automation groups & research institutes (multi-point sensing systems).

We have delivered over 600,000 sensor modules, supporting nearly 100 custom configurations with high yield and reliable technical support — earning global customer trust and recognition.

What is a Load Cell?

Load Cell is a sensor element that converts mechanical force (such as weight, pressure or tension) into a readable electrical signal. It is widely used in automation equipment, electronic scales, industrial control, smart manufacturing and mechanical measurement systems. According to different sensing principles, common load cell types include:Strain Gauge Load Cell: The most common type, which produces resistance changes through deformation of the strain gauge.Piezoelectric Load Cell: Generates voltage through the piezoelectric effect, suitable for dynamic measurement.Electromagnetic, hydraulic and pneumatic load cells: choose according to application requirements and suit specific environments.Load Cell Technology Advantages

High precision and stabilityStrong anti-interference ability, suitable for harsh environmentsCan be integrated with various amplifiers, displays, PLCs and IoT systemsModular design to support customized application requirementsLoad Cell Application Areas

Load Cells play a key role in many industries, including:Semiconductor process and precision manufacturing: used for wafer carrier weight monitoring and force control assemblyAutomation equipment and robotic arms: real-time sensing of gripping force and object weightLogistics and warehouse management system: automatic weighing, intelligent sortingMedical and healthcare equipment: Accurately measure patient weight or weight changesAgriculture and food processing: material monitoring and packaging weighing applicationsLoad Cell Future Development Trend

Smart Sensing Modularity

Load Cell will integrate more IoT wireless transmission, sensing algorithms and real-time monitoring functions to provide a complete smart sensing solution.High integration and miniaturized design

To meet the needs of precision equipment, Load Cell will develop in the direction of miniaturization, high density and modularization in the future to enhance system integration and installation flexibility.AI mechanical data analysis import

Combining AI and big data platforms for predictive maintenance and mechanical anomaly detection, Load Cell is no longer just a sensor, but also an important part of the intelligent decision-making system.High reliability and improved environmental adaptability

In response to extreme temperature, humidity and corrosive environments, we will develop more load cell products with high protection levels (such as IP68) and high-durability materials.Why choose our Load Cell solution?

We have many years of experience in sensor research and development, focusing on providing:High-precision Load Cell design and customized developmentComplete technical support and system integration servicesFast delivery and stable supply capacityISO certified and protected by patents in multiple countriesWhether you are a R&D engineer looking for high-precision sensing solutions, an equipment engineer performing system integration, or a company purchaser evaluating stable suppliers, we can be your reliable partner!

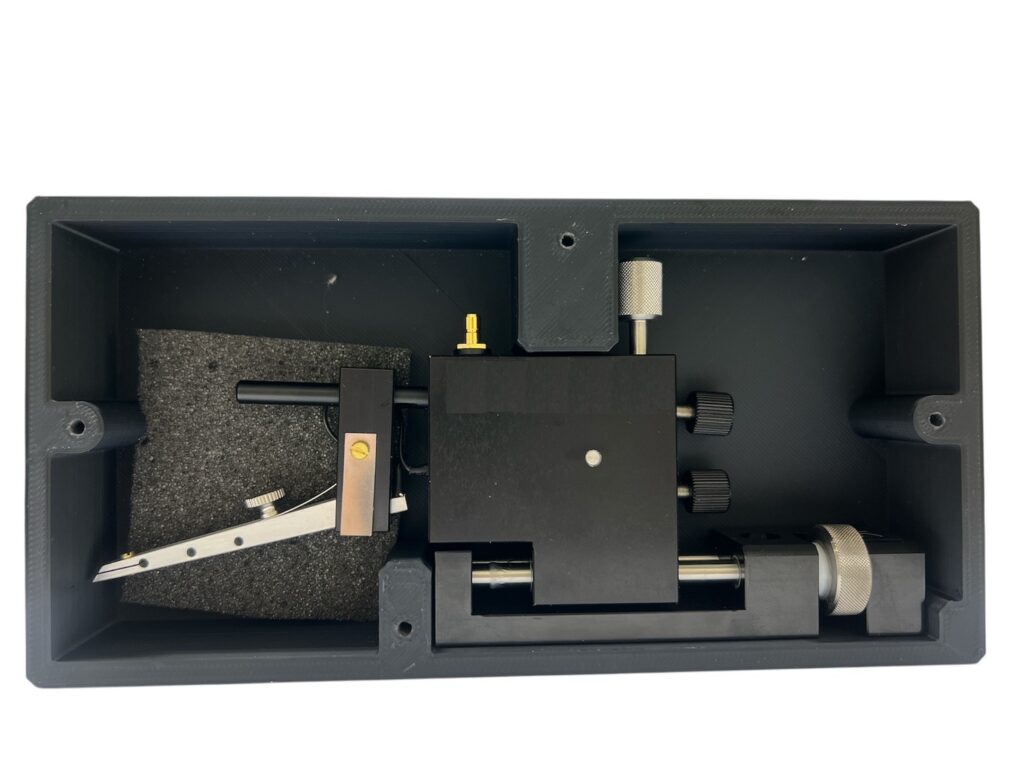

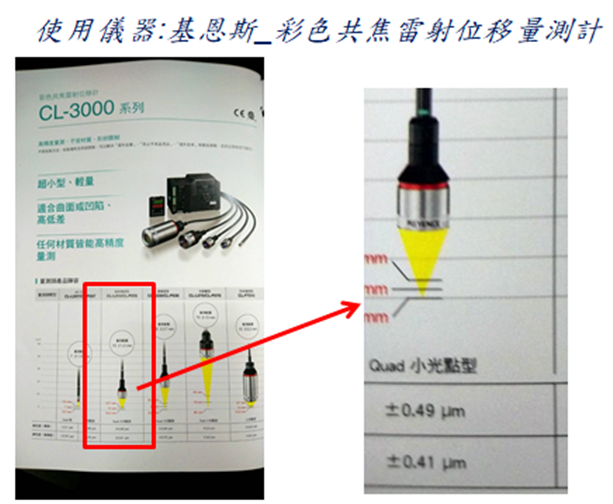

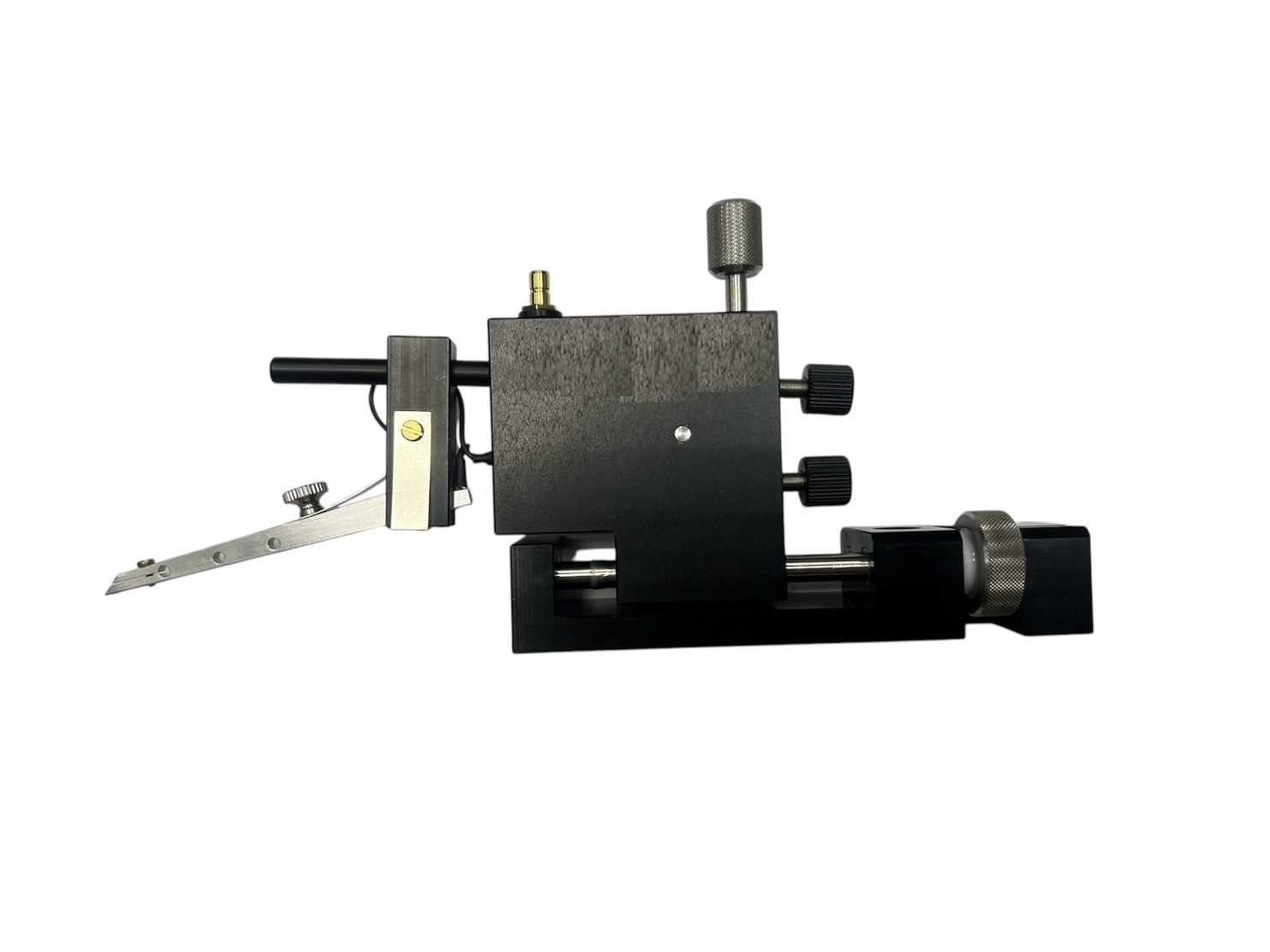

Load cell displacement measurement and analysis

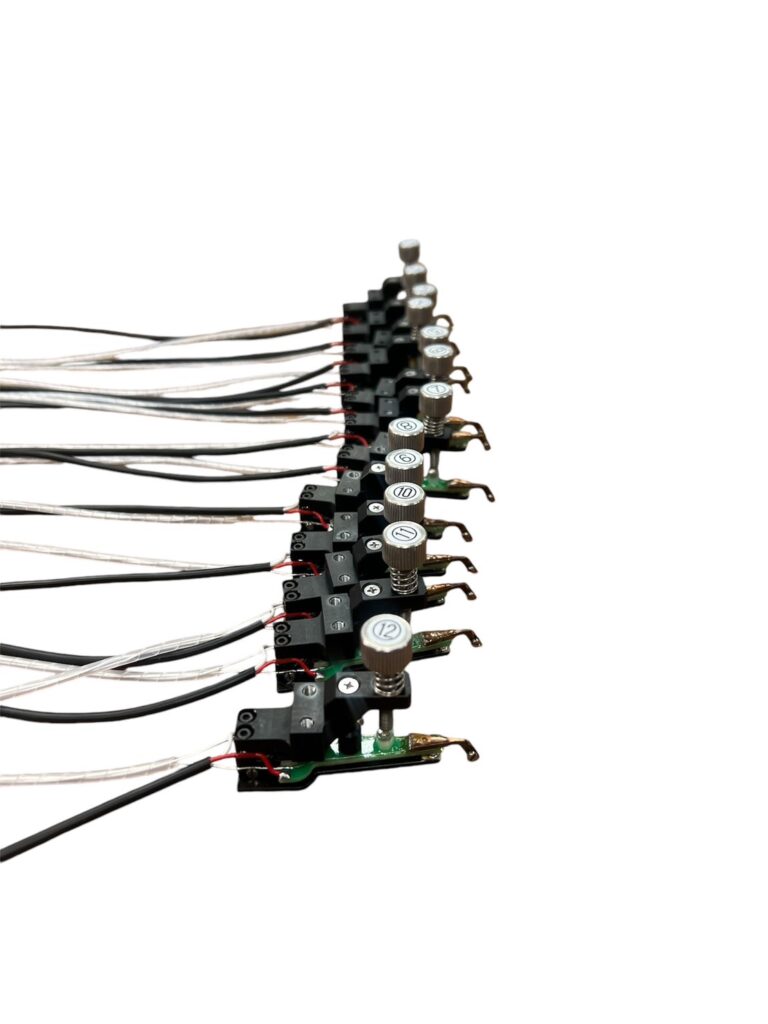

Probe Card / Edge Sensor

Edge Sensor Probe Holder Technology: Best Choice for Die (Wafer) Point-to-Point Probing and Probe Solutions

📞 Contact Us for Professional Load Cell Integration Support

Whether you are an R&D team, equipment manufacturer, OEM assembler, or turnkey system integrator, we provide comprehensive solutions tailored to your specific application needs.

📧 Email: chtco@chtco.com.tw

🌐 Website: www.chtco.com.tw

📞 Phone: +886-4-24263929