CHTCO is centered on a world-class precision die stamping and mechanical design team with highly professional and rich experience in Metal frame/Cassette/Magazine production and design, and has established a strong linkage partnership with global IC/LED/Solar customers. Our mission is to provide the highest quality products in the industry and to increase the price competitiveness for our customers:

- Highest quality iron ring supplier

- The most professional Cassette supplier

- Precision shaping

More than ten precision shaping equipment and decades of sheet metal shaping experience and technical database ensure that the sheet metal flatness meets SEMI production standards.

- Professional extrusion equipment

Large-scale aluminum extrusion forming equipment provides customers with a full range of aluminum extrusion processing and manufacturing services including various aluminum extrusion design, mold opening, manufacturing, aluminum material processing, etc.

- Automatic grinding and polishing

Since manual polishing can result in uneven quality, CHT is the only technology leader in Taiwan that has collaborated with Japanese technology to introduce fully automatic grinding and polishing processes, ensuring high product yield and uniform quality.

- Mass production technology

With over ten years of experience in aluminum extrusion production, we are one of the most professional aluminum extrusion manufacturers in Taiwan. Our company has more than 100 types of aluminum extrusion styles and assembly accessories, which are sufficient to meet the needs of general Cassette production and ensure high product yield.

- Vacuum heat treatment

Taiwan’s most professional heat treatment equipment and optimized heat treatment process parameters. Quenching + tempering adjusts the Film Frame hardness to HRC 47. Higher hardness, more resistant to blade cutting, and longer service life of the Film Frame.

- Professional heat treatment

With a professional heat treatment team, combined with more than 10 years of process production experience, we have established standard heat treatment technology and strict temperature curve control guidelines to achieve higher strength and durability of products.

- Forming

With more than dozens of punching dies and forming equipment, we also provide deeper knowledge of punching dies and a team of engineers with rich sheet metal forming experience, dedicated to speeding up your product’s time to market.

- Precision CNC manufacturing

We have professional experience and technology in CNC processing, and we continue to develop processing technology and expand precision equipment to provide customers with better production flexibility and shorten delivery cycle.

- Sources

We use high-quality SUS420J2 stainless steel from Japan JEF and cooperate with Japan JFE Steel to obtain high-quality steel materials stably. The only thing we can guarantee is that we only use JEF’s high-quality SUS420J2 stainless steel material.

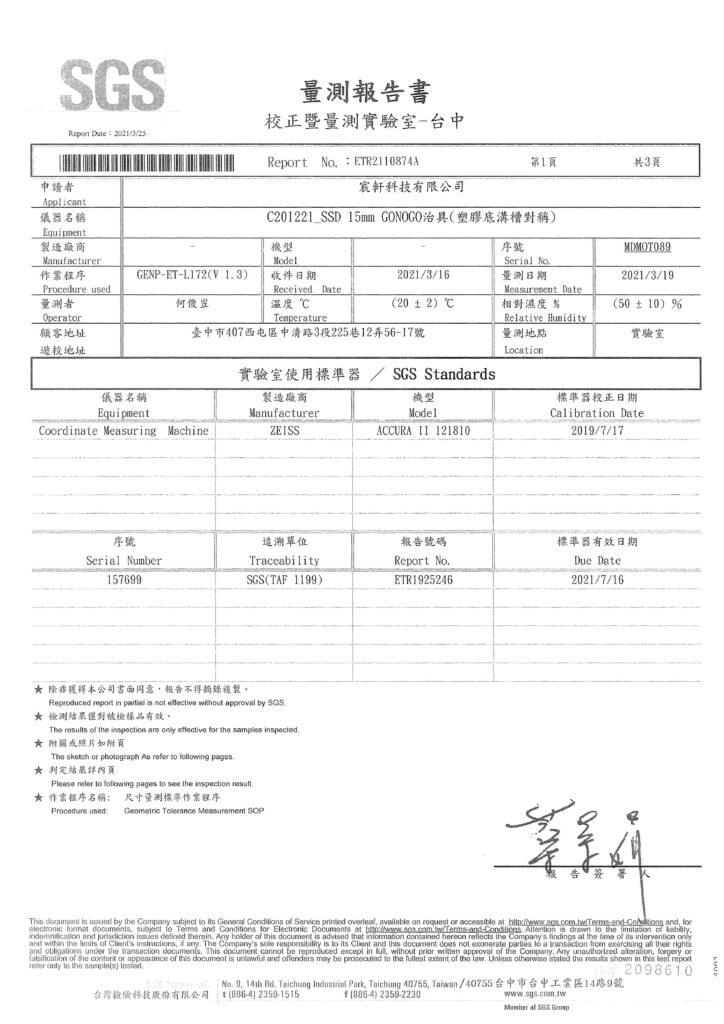

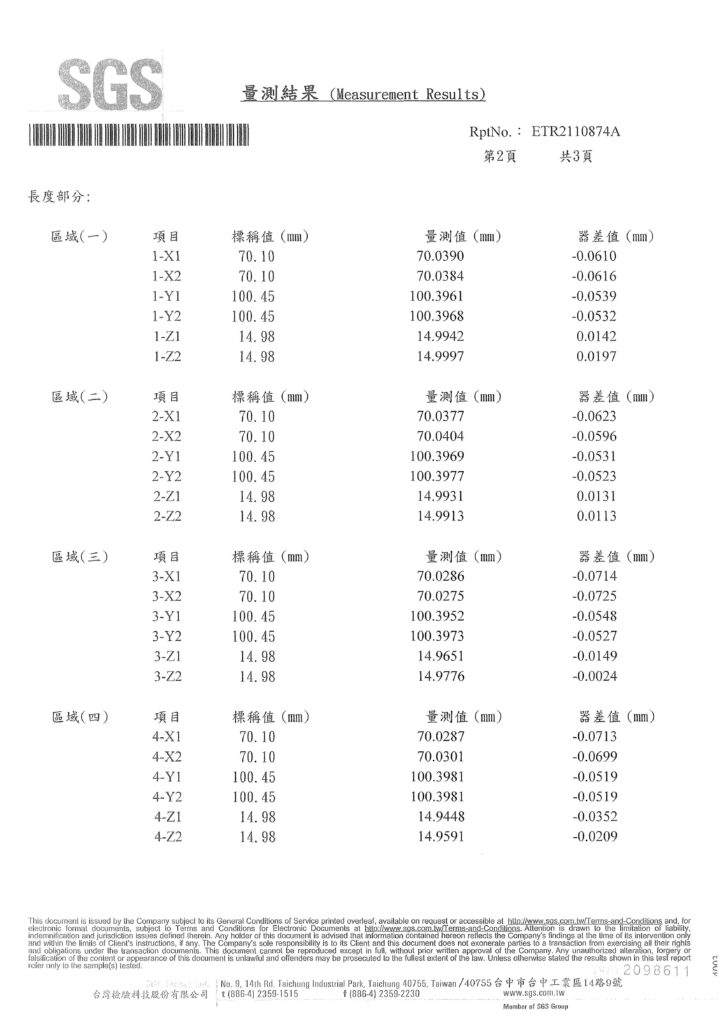

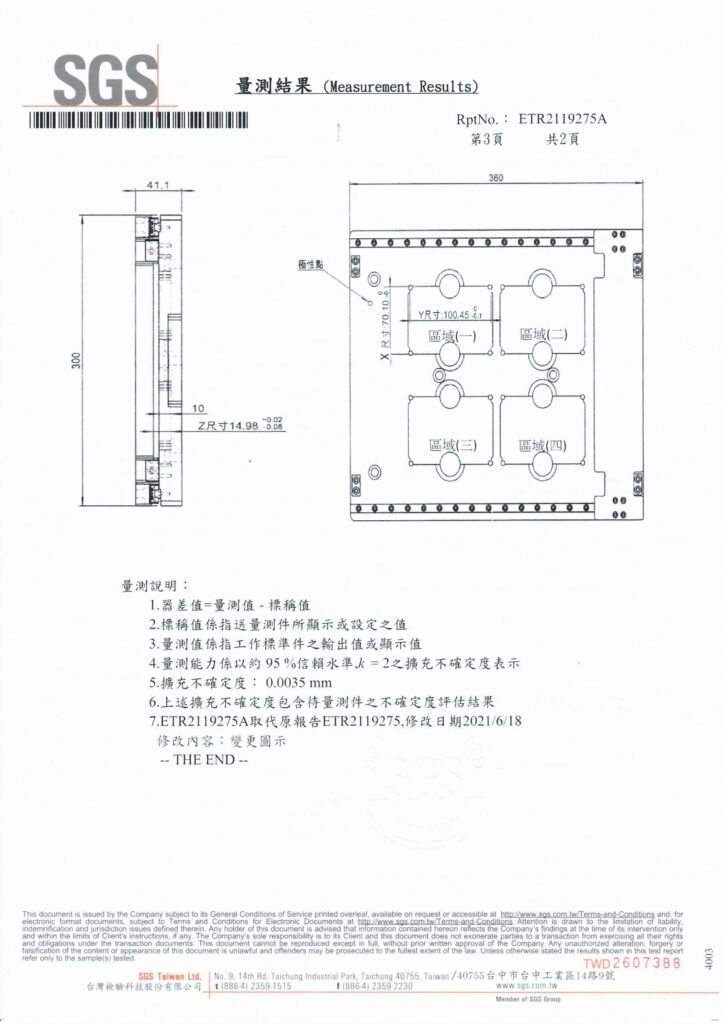

- Precision measuring instruments

We have introduced three-dimensional measuring machines and various precision measuring instruments and conduct regular inspections to ensure that production quality meets customer needs.

- Ultrasonic cleaning anti-oxidation technology

Imported Japanese ultrasonic cleaning/baking/anti-oxidation treatment in-line equipment, using Japanese 6-tank 6-pass process to meet high-standard cleaning and anti-oxidation treatment requirements. Other companies only use a 3-tank ultrasonic water washing process, which has limited anti-oxidation function.

- Customized design service

With sufficient design capabilities and equipment support, we can provide customers with finished products within 2 weeks based on customized production requirements, shortening the customer’s R&D schedule and providing better competitiveness.

SSD 15mm GO NO GO fixture SGS verification certificate

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.