Design and Manufacture of Daughter Rings (Expansion Rings, Crystal Expansion Rings)

What is a Grip Ring?

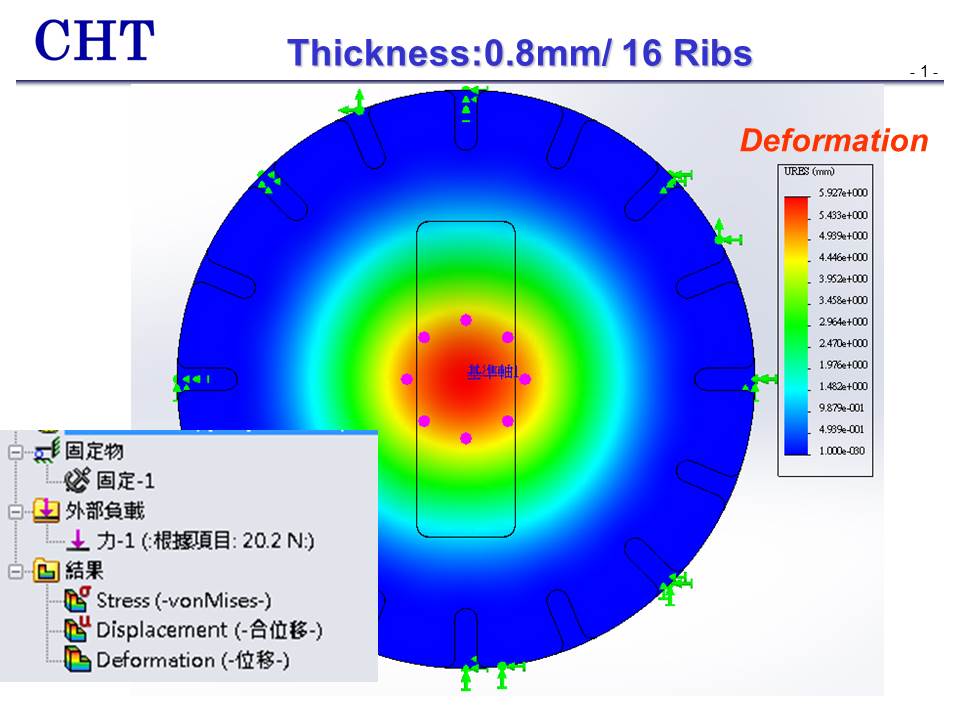

The Grip Ring (also known as the expansion ring/wafer expansion ring/grip ring) is a key component designed for wafer fixation and LED/IC wafer carrier applications. Through mechanical expansion and high-density design, the mother-and-child ring can firmly attach the wafer to the film surface, ensuring positioning stability and product yield during transportation, processing and packaging.The GR series of mother and daughter rings launched by our company are made of high-strength materials and precision processes, providing world-class expansion performance and life guarantee. They are indispensable precision carrier components for various semiconductor, LED, optoelectronic, and packaging and testing production lines.Key technical development points for GR series mother-child rings✅High compactness and stable expansion design

🛠Clamping force/rebound force adjustment:Precision design based on actual process mechanics requirements

🧪 On-site testing and sample provision:Can assist customers with on-site matching evaluation and performance verification

📈 Rapid prototyping and mass production support:Own precision processing production line to shorten the development to mass production cycleWhy choose us as your ring supplier?

- Precision machining mechanism design to achieve uniform expansion and high tightness fit

- Effectively prevent wafer displacement, deflection or warping during the process

- Supports multiple wafer sizes (such as 6-inch, 8-inch, 12-inch) and is compatible with a variety of materials

- Adopting the plastics of international first-class chemical plants, we can assist in customization with anti-corrosion, fatigue, high temperature resistance.

- Passed more than one million expansion cycle tests, the service life is much longer than the general commercially available standard parts

- Suitable for long-term high-frequency production line use, reducing replacement costs and maintenance risks

- Compatible with a variety of automated wafer handling or process equipment

- Supports customized clamping force / expansion force adjustment, flexibly applied to different process requirements

- 🔹 LED chip fixing and bonding process

- 🔹Semiconductor wafer cutting/grinding/testing/packaging

- 🔹 Photoelectric sensing element (such as CMOS, image sensor) processing

- 🔹 High-end IC carrier / precision ceramic substrate processing and fixing

- 🔹 Display panel module frame fixing

- The expansion repeatability error is controlled within ±0.2mm

- The industry’s highest service life and tensile test strength

- Can assist in customization with surface treatment, clean room grade anti-oxidation, anti-corrosion and anti-static treatment

- Each batch of production is accompanied by an inspection report and material certificate

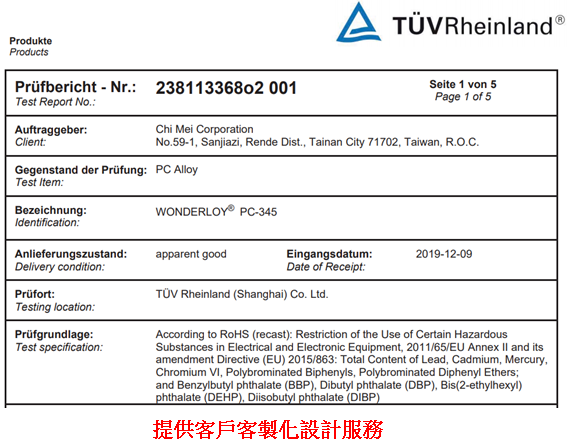

- All products comply with RoHS and international environmental regulations

🛠Clamping force/rebound force adjustment:Precision design based on actual process mechanics requirements

🧪 On-site testing and sample provision:Can assist customers with on-site matching evaluation and performance verification

📈 Rapid prototyping and mass production support:Own precision processing production line to shorten the development to mass production cycleWhy choose us as your ring supplier?

- 🌟 More than 10 years of experience in the wafer and precision components market

- 🌟 Possess one-stop integration capabilities of R&D, design, mold and manufacturing

- 🌟 Serving many leading semiconductor and LED manufacturers, with high trust

- 🌟 Flexible production + fast delivery + high-standard testing to ensure both quality and efficiency

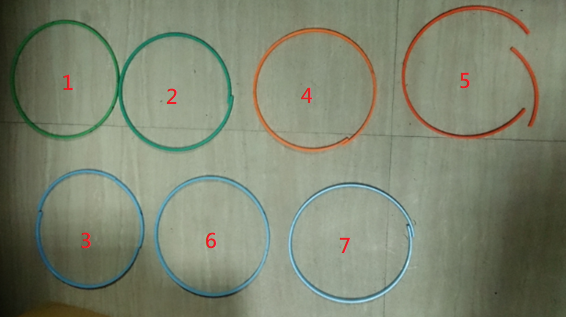

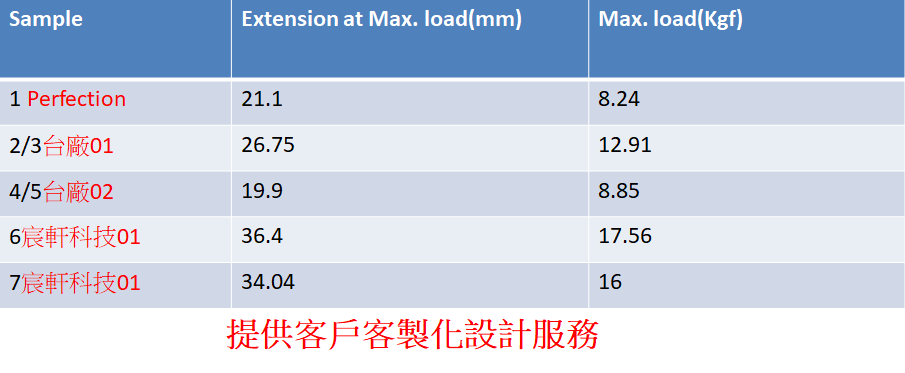

Mother-child ring (expansion ring, crystal expansion ring) tensile test experiment-equipment

Testing unit: Stanley R&D and Design Center

Stretching rate: 1mm/sec

Pre-load :3kgf

Results of the tensile test of the mother-child ring (expansion ring, crystal expansion ring)

PC material can be used in acid and alkali resistant environment and child rings (expansion rings, crystal expansion rings) is excellent, higher than the industry standard!!

PC material can be used in acid and alkali resistant environment

Products comply with RoHS standards

And there is an anti-static shipping box for use

Customized color or other project structure can be developed.

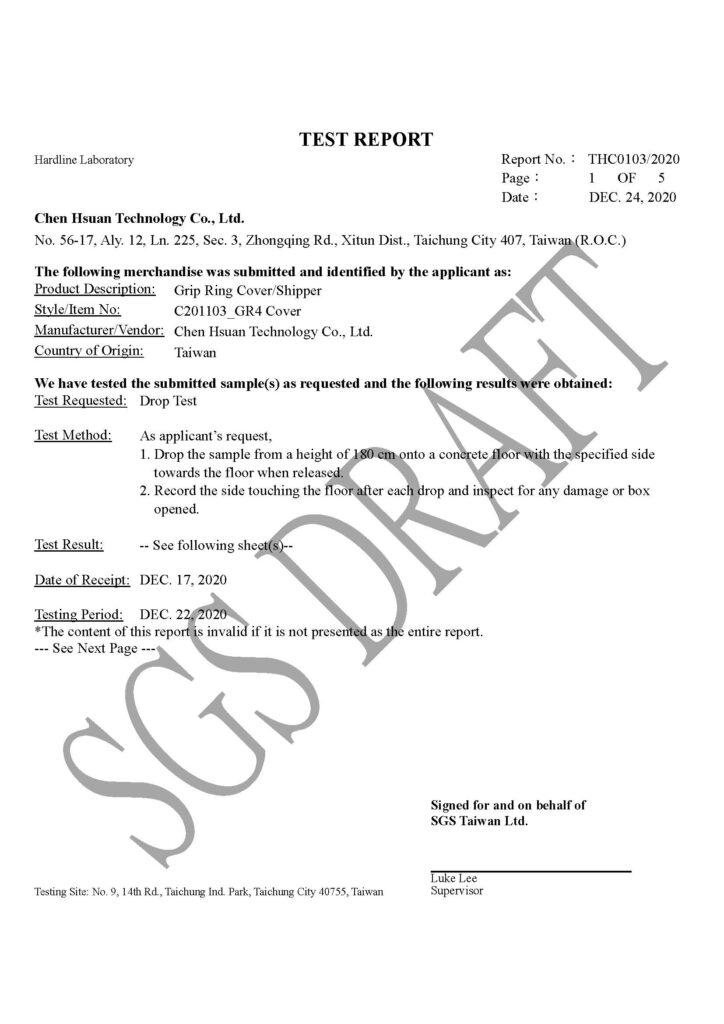

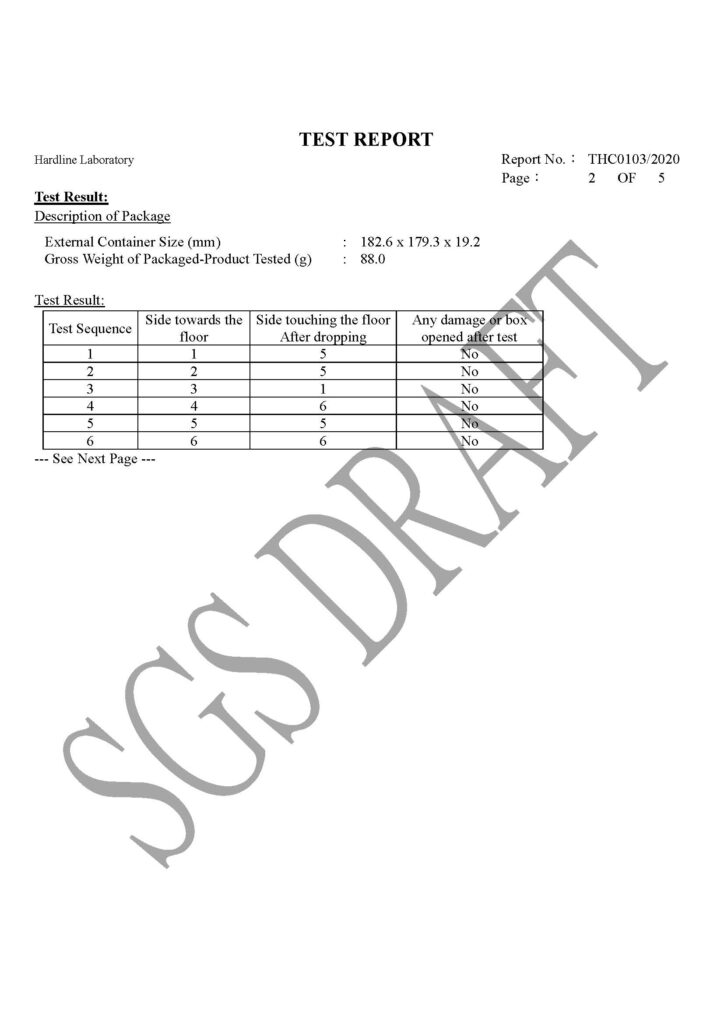

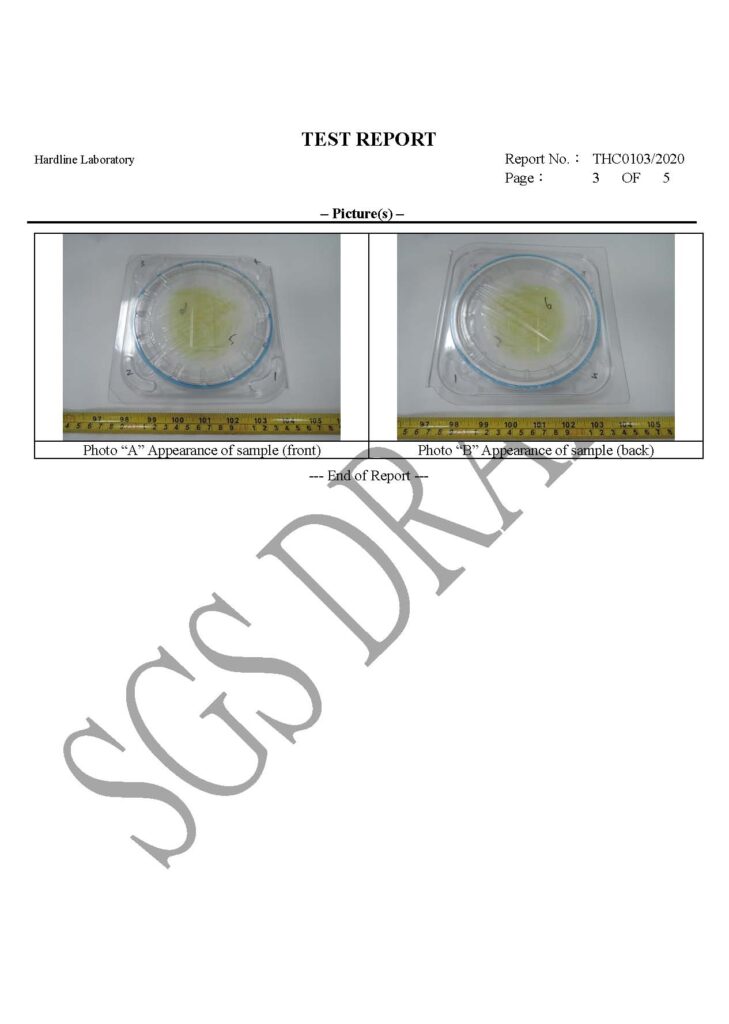

SGS drop test certificate for mother-child ring (expansion ring, crystal ring) shipping box

SGS drop test certificate for mother-child ring (expansion ring, crystal ring) shipping box

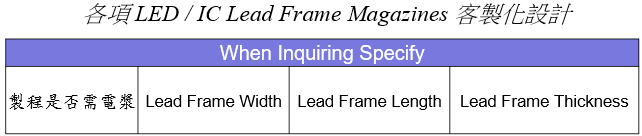

Magazines and carrier systems specified by global packaging manufacturersChenxuan Technology focuses on the design and manufacturing of magazines/cassettes/wafer frames/magazines for semiconductor automation production lines. Its products are sold all over the world and are widely used in core packaging equipment such as die attach machines and wire bonders.

We have developed hundreds of series models,which have been successfully introduced into major semiconductor manufacturing centers in Taiwan, China, Japan, South Korea, the United States, Europe, etc., and have been listed as qualified suppliers by many international packaging manufacturers.The Application and Importance of Cassette / Wafer Frame / MagazineIn the semiconductor packaging process, various carrier systems (such as magazines, cassettes, wafer frames, magazines) are responsible for carrying wafers, chips or frames to ensure their stability and accuracy during transportation, loading and unloading of automated machines, and process alignment.

Its design must meet the following requirements:

📊 Each batch comes with detailed size test report and material certificate

🌡 Passed high and low temperature cycle test, chemical resistance test, life simulation

🧪 Regular sample aging and pressure testing to ensure that the reuse life is higher than the industry standard

🧼 Supports Class 100 cleanroom cleaning standardsCustomized manufacturing capabilities | One-stop vehicle solutionsWe not only provide standard products, but also specialize in designing and manufacturing according to customers’ special needs:🔧 Special card slot design, frame fixed structure, stacking or flipping structure improvement

🔧Provide 3D simulation and proofing services for special-shaped products, special packaging types, and non-standard specifications

🔧 Fast prototyping, low MOQ, small batch manufacturing support

🔧 Cooperate with customers’ automated production lines and equipment manufacturers to jointly develop docking modulesReasons for choosing Chen Hsuan Technology

We have developed hundreds of series models,which have been successfully introduced into major semiconductor manufacturing centers in Taiwan, China, Japan, South Korea, the United States, Europe, etc., and have been listed as qualified suppliers by many international packaging manufacturers.The Application and Importance of Cassette / Wafer Frame / MagazineIn the semiconductor packaging process, various carrier systems (such as magazines, cassettes, wafer frames, magazines) are responsible for carrying wafers, chips or frames to ensure their stability and accuracy during transportation, loading and unloading of automated machines, and process alignment.

Its design must meet the following requirements:

- High-precision positioning

- High temperature and chemical resistance

- High repetitive use life

- Automation machine compatibility

- Covers various IC carrier sizes (6″, 8″, 12″, etc.) and is compatible with all mainstream equipment specifications

- Optimized design can be performed based on specific wafer thickness, frame shape, and carrier weight

- Provides advanced mechanisms such as vacuum adsorption, spring elastic structure, and guidance positioning system

- Use high-strength anti-static plastics (such as PEEK, PPS, ESD-ABS), high-grade aluminum or stainless steel

- The material has anti-wear, high temperature tolerance and low particle characteristics, meeting the requirements of clean room grade

- Strictly control the source of materials and comply with international regulations such as RoHS and REACH

- We built a fully automated chemical plant in Taiwan to achieve CNC processing, injection molding, assembly and testing.

- Precision controlled within ±0.2mm, stable supply of large orders

- Automatic inspection system to ensure 100% compliance of dimensions, tolerances and fit

📊 Each batch comes with detailed size test report and material certificate

🌡 Passed high and low temperature cycle test, chemical resistance test, life simulation

🧪 Regular sample aging and pressure testing to ensure that the reuse life is higher than the industry standard

🧼 Supports Class 100 cleanroom cleaning standardsCustomized manufacturing capabilities | One-stop vehicle solutionsWe not only provide standard products, but also specialize in designing and manufacturing according to customers’ special needs:🔧 Special card slot design, frame fixed structure, stacking or flipping structure improvement

🔧Provide 3D simulation and proofing services for special-shaped products, special packaging types, and non-standard specifications

🔧 Fast prototyping, low MOQ, small batch manufacturing support

🔧 Cooperate with customers’ automated production lines and equipment manufacturers to jointly develop docking modulesReasons for choosing Chen Hsuan Technology

- ✅ Over 10 years of experience in R&D and manufacturing of semiconductor carriers

- ✅Long-term partner of the world’s leading packaging and testing company

- ✅ Made in Taiwan, automated production lines ensure stable delivery

- ✅ The technical team can provide real-time support and rapid customized proofing

- ✅Competitive prices help customers effectively control costs

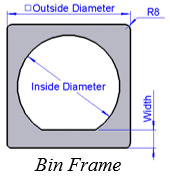

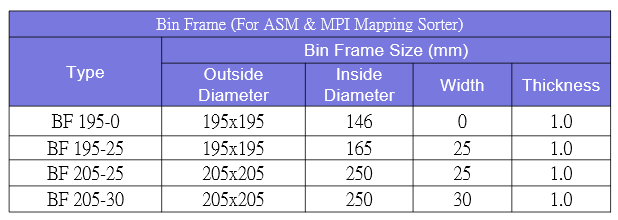

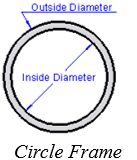

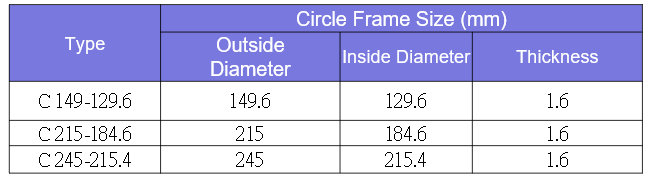

Film Frame Product

Our ranges of Metal Frames can handle wafers up to 300mm, and also customizable to suit user’s requirements

Customized specifications is available

Cassette/Magazine Product

Customized specifications is available