Optical lens

AOI/Machine Vision Lens | High resolution, high stability, high customization, accurate and reliable automatic optical inspection key imaging core

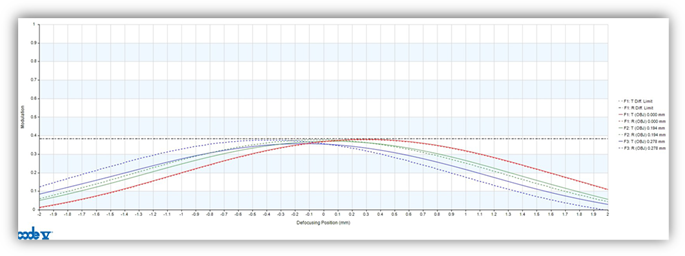

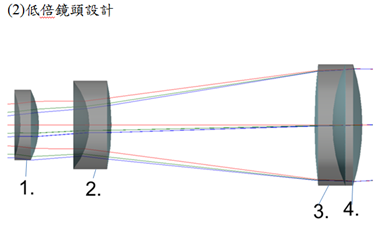

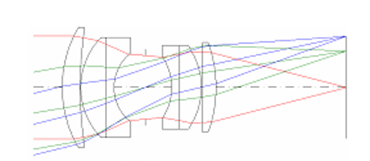

In automatic optical inspection (AOI) and machine vision systems, the lens is the first step in the imaging system and is the key to overall inspection accuracy, efficiency, and stability. Chenxuan Technology has been deeply involved in the field of high-precision optics and provides professional lens solutions designed specifically for AOI and vision systems. It supports a variety of sensor sizes, field of view, and magnification requirements, and can customize the design of lens modules based on the application to help improve equipment recognition performance and reliability.Technology Development Focus|Creating the best lens solution for image detection tasks🔬 High resolution for various sensor sizesSupports various sensor sizes from 1/3″, 1/2″, 2/3″, 1″ to APS-C, and is designed to meet 4K/8K image output requirements:

Ensure that the resolution meets the standards and provide measurement reports for customer traceability.🎯 Centration & Decentering Measurement

Ensure the precise consistency of lens assembly and optical axis.📦Dust-free assembly and packaging process

Manufactured in a Class 1000 clean room and vacuum packed to ensure shipment quality.🧰 100% factory tested and verified:

✅Small quantity, diverse quantity and fast delivery:New projects quickly enter the verification phase

✅ Complete optical design and system integration capabilities:Supports various light sources and sensor matching

✅ Stable yield, certified by many semiconductor equipment manufacturers

- Resolvable below 3μm

- Solving the challenge of identifying small defects

- Supports color and black and white sensor compatibility

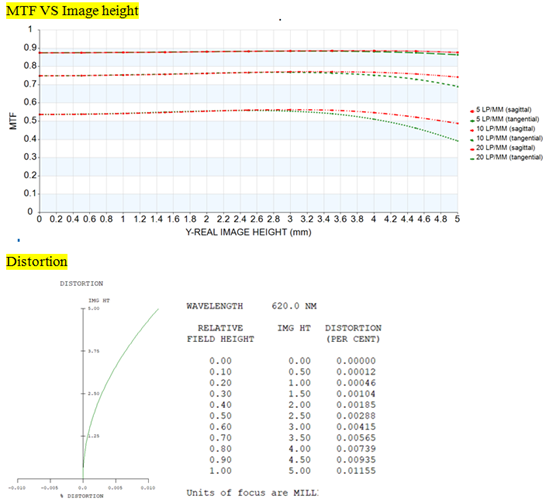

- Distortion

- Chromatic Aberration

- Flare and Ghost

- High Precision Parts Inspection

- Wafer appearance defect analysis

- Alignment and packaging visual positioning

- Fixed focus/Zoom lens

- Telecentric Lens

- High NA design (high numerical aperture, improved light collection efficiency)

Ensure that the resolution meets the standards and provide measurement reports for customer traceability.🎯 Centration & Decentering Measurement

Ensure the precise consistency of lens assembly and optical axis.📦Dust-free assembly and packaging process

Manufactured in a Class 1000 clean room and vacuum packed to ensure shipment quality.🧰 100% factory tested and verified:

- Imaging Tests

- Locking screw inspection

- Appearance and durability test

- Specification discussion and application scenario analysis

- Optical design (Zemax), mechanical design (SolidWorks)

- Lens sample proofing and function verification

- Small-scale trial production and mass production with fast delivery

Typical application scenarios

| Application areas | Key features of the lens |

| Semiconductor wafer and IC package inspection | High resolution + low distortion + telecentric design |

| Panel and PCB appearance inspection | Wide field of view + uniform imaging + multiple magnification support |

| Medical and biotechnology equipment vision systems | Macro clarity + true color imaging + high stability |

| Automated equipment positioning | Fast focus + low-latency imaging + long-term stable operation |

Why choose AOI lens solutions from Chenxuan Technology?

✅ Developed and manufactured in Taiwan:Shorten development cycle and provide immediate maintenance support✅Small quantity, diverse quantity and fast delivery:New projects quickly enter the verification phase

✅ Complete optical design and system integration capabilities:Supports various light sources and sensor matching

✅ Stable yield, certified by many semiconductor equipment manufacturers

Optical devices

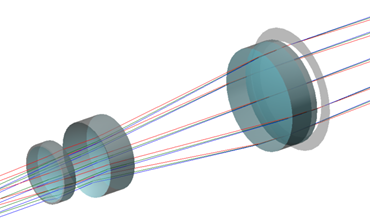

Lens

A lens is an optical element that uses its curved surface to change the direction of light propagation, thereby achieving the effect of focusing or diverging light. According to the shape and function, lenses can be divided into convex lenses and concave lenses. Convex lenses are usually used to converge light, while concave lenses are used to disperse light. Lenses are widely used in optical equipment such as glasses, microscopes, cameras, and telescopes. Their design and manufacturing require sophisticated technology to ensure the accuracy and stability of optical performance.

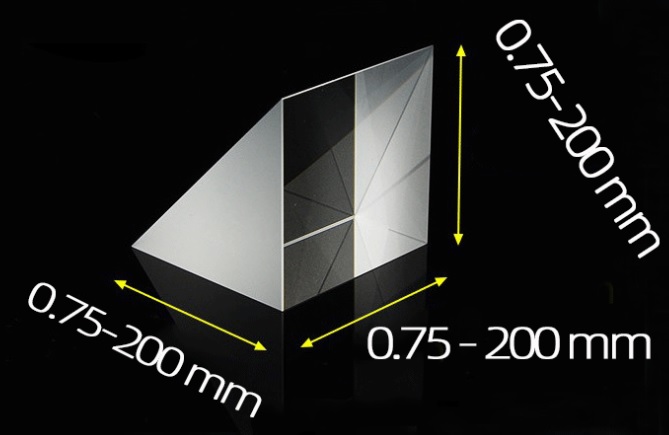

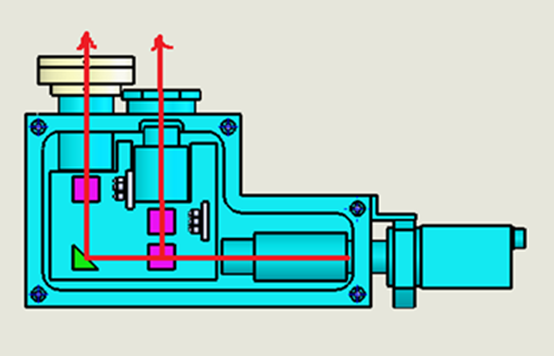

Prism/Spectroscope

A prism is an optical element that is usually designed with multiple plane mirror surfaces arranged in a specific geometrical arrangement. Its main function is to change the direction of light, reflect light or split light. It is commonly used in optical instruments such as telescopes, cameras, microscopes and laser equipment.The structure of a prism is usually made of glass or transparent materials, and the surface is precisely cut and polished to ensure that light can be accurately reflected or refracted along the designed path. Depending on the purpose, prisms can be divided into many types, such as:

- Reflective mirror:Used to change the direction of light, commonly seen in telescopes.

- Spectroscopic prism: used to decompose light into different wavelengths and applied to spectral analysis.

- Polarizing mirror: used to separate or adjust the polarization direction of light.

- Total reflection prism: uses the total reflection phenomenon to achieve efficient reflection of light.

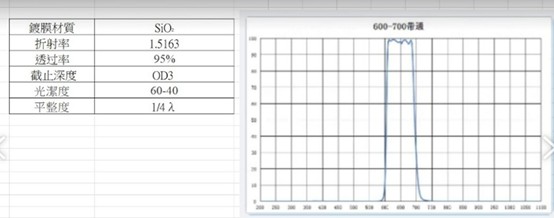

Filter

A filter is an optical device used to selectively pass or block light of a specific wavelength. Filters are widely used in photography, imaging, scientific research, and other fields. Here is some basic information about filters:

Types of filters

- Color filter:

- Used to change the color of an image or enhance the effect of a specific color.

- Common in photography and videography.

- Polarizing filter:

- Used to reduce reflected light and improve color saturation.

- Often used in outdoor photography, especially when photographing water or glass.

- Neutral Density Filter (ND Filter):

- Used to reduce the amount of light entering the camera without changing the color.

- This allows for slower shutter speeds to be used in bright light environments.

- UV filter:

- Used to filter ultraviolet light and protect the lens.

- Although modern digital cameras are less sensitive to UV light, it can still be used to protect the lens.

尺寸皆可客制