AOI (machine vision) light source design and manufacturing

What are the lighting sources used in AOI and machine vision?

In automatic optical inspection (AOI) and mechanical vision systems, light source is the key factor in determining image quality. Through the design of highly stable, highly uniform, and highly contrasting dedicated light sources, image recognition rate, defect detection rate, and production quality stability can be greatly improved.Our company is committed to the research and development and manufacturing of AOI / mechanical vision light sources, and our services cover various industries such as semiconductors, PCB, TFT-LCD, electronic assembly, automation equipment, precision parts inspection, medical image processing and smart manufacturing.AOI / Machine Vision Light Source Technology Development Focus

✅ Passed luminous intensity distribution analysis / stability record / EMI test

✅ All products comply with RoHS international standards

✅ We can provide third-party inspection reports and test data records according to customer needs.Customization is our core competitivenessWe know that the optical requirements of each AOI or mechanical vision system are different, so we provide a complete customized service process:🔧 Quick Case Evaluation:Provide professional selection suggestions and system matching consultation🧪 Optical Simulation and Sample Verification:Can assist customers with on-site image testing and evaluation

🛠 Modular design and production:Support small quantity and variety, fast delivery, and flexible manufacturing

🤝One-to-one project collaborative development:Work closely with R&D or device engineers to improve development efficiencyWidely used in service industries

- Light pattern design and uniformity control

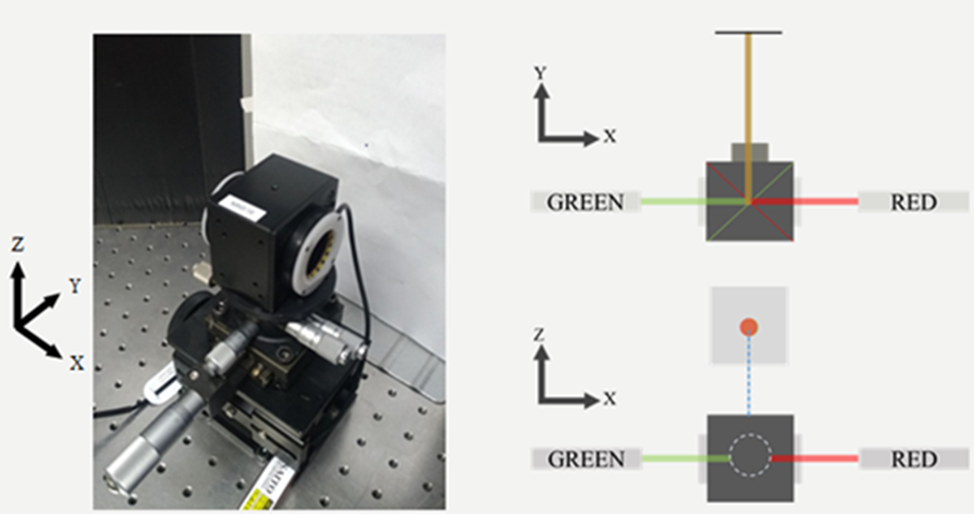

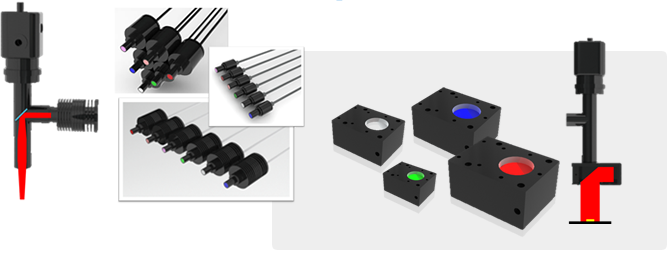

- Coaxial light, ring light, backlight, strip light, surface light source, oblique light, multi-angle light source

- Using optical simulation software for light distribution design

- Ensure illumination uniformity of more than 95%, eliminating shadows and hot spots

- High stability drive circuit design

- Constant current drive and low noise control IC are used to ensure the brightness stability of the light source is better than ±1%

- Equipped with overvoltage protection and thermal protection mechanisms to improve durability and safety

- Multiple modes can be selected, including PWM dimming, external triggering or synchronous control

- Multi-wavelength/multi-spectral design

- Available in red, blue, green, white, ultraviolet, infrared and dual wavelength combinations

- Combined with image processing software algorithms, it improves defect separation and contour enhancement capabilities

- Suitable for transparent object detection, reflective surface, package defects, IC pins, etc.

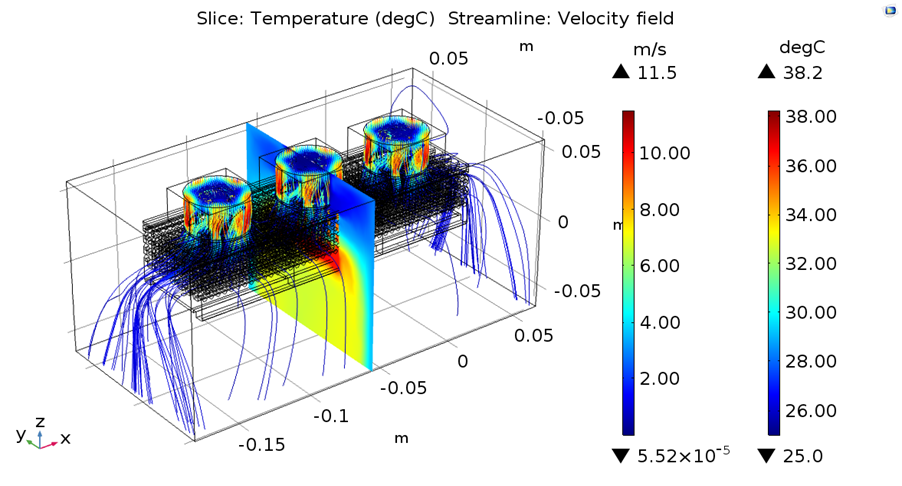

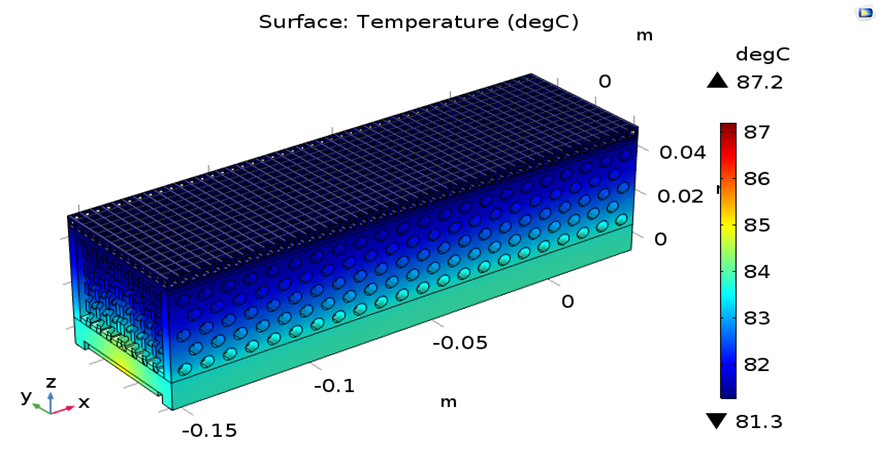

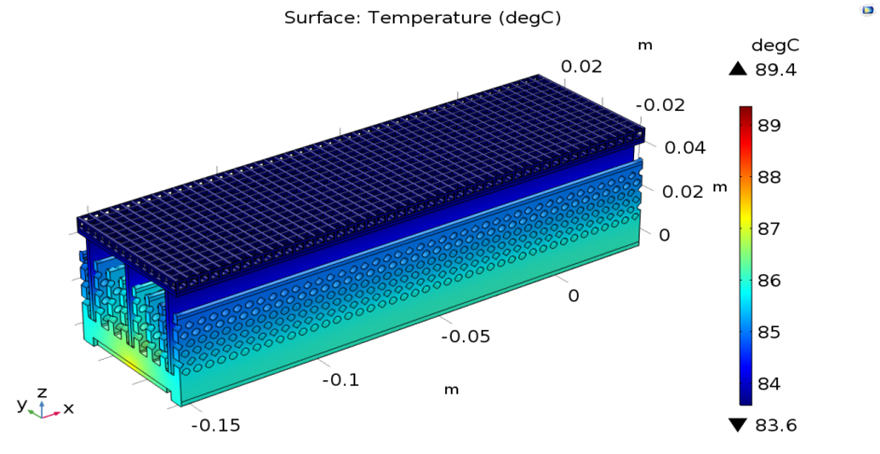

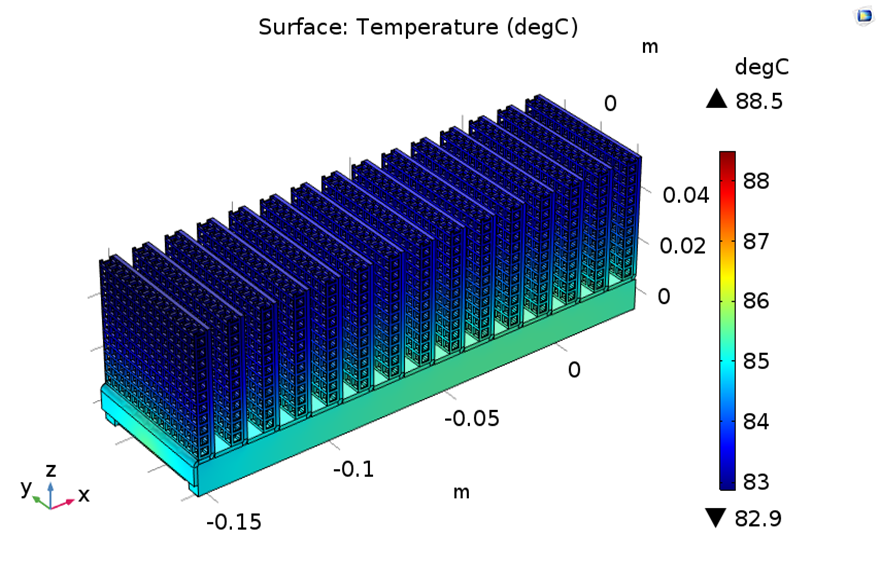

- Adopt high thermal conductivity aluminum substrate and special heat dissipation structure design

- Passed high temperature aging test and life simulation test, the life span can reach more than 40,000 hours

- Ensure that the light color and illumination remain stable under long-term use

✅ Passed luminous intensity distribution analysis / stability record / EMI test

✅ All products comply with RoHS international standards

✅ We can provide third-party inspection reports and test data records according to customer needs.Customization is our core competitivenessWe know that the optical requirements of each AOI or mechanical vision system are different, so we provide a complete customized service process:🔧 Quick Case Evaluation:Provide professional selection suggestions and system matching consultation🧪 Optical Simulation and Sample Verification:Can assist customers with on-site image testing and evaluation

🛠 Modular design and production:Support small quantity and variety, fast delivery, and flexible manufacturing

🤝One-to-one project collaborative development:Work closely with R&D or device engineers to improve development efficiencyWidely used in service industries

Our light sources have been successfully applied in the following fields:

- ✅Semiconductor Wafer Defect Inspection

- ✅ PCB and SMT component position/short circuit detection

- ✅ Panel bright spot/foreign object inspection

- ✅ Precision screw size measurement

- ✅ Glass crack and coating defect detection

- ✅ Packaging and barcode OCR recognition

Latest Products

Light source catalog

- External coaxial light source IFVL series

- Internal coaxial light source HV series

- High Angle Ring Light Source DR Series

- Low Angle Ring Light Source LDR/FDR Series

- High brightness high angle ring light source HDR/HRL series

- Shadowless Light Source PR/PRS Series

- High brightness low angle ring light source HLD/HRL series

- DB series strip sidelight

- High Brightness Bar Light HDB Series

- High brightness thin backlight source TH/THR/BL/DBS series

- STH series thin backlight source

- Concentrated Line Light Source LN/HLN Series

- High brightness side light source SL/SLP series

- HPD Series

- Integrated light source MLI series

- LED Ring Light DRMS Series

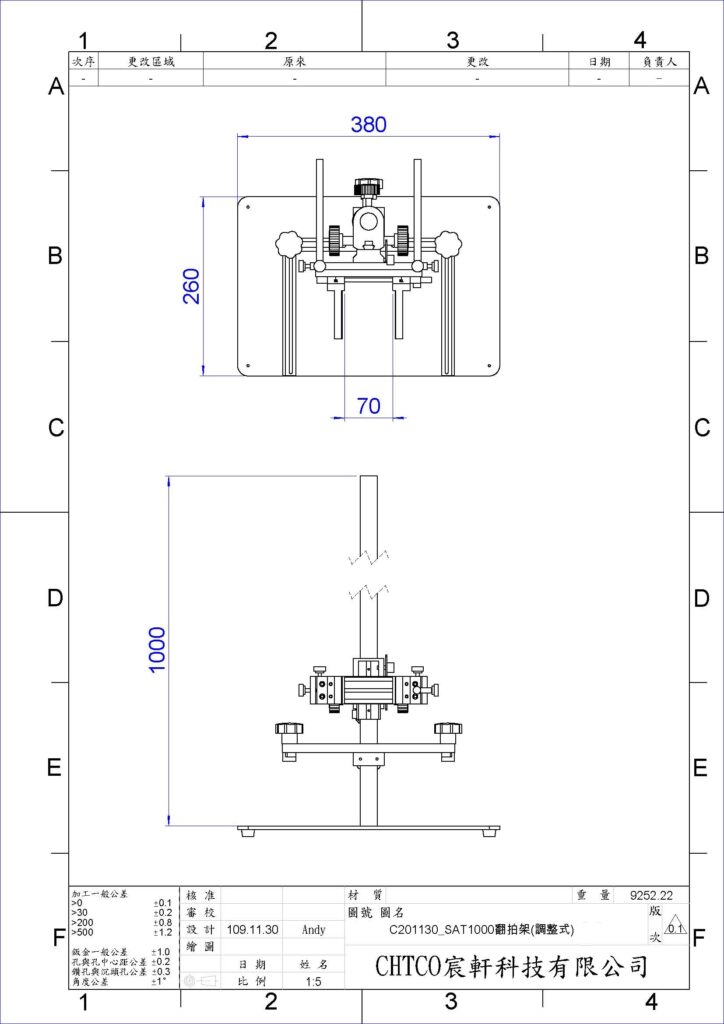

- Copy stand/tilt fine adjustment platform/three-axis adjustment stand/microscope adjustment stand SAT/AJAS series

- Optical Glass PZC Series

- Standard and customized calibration sheets (masks) production and cutting

- AOI dedicated intelligent LED light source controller 2.0 camera handshake board

- Constant Current Dimming Controller SAT-CP Series

Perform numerical simulation design and verify the final heat dissipation design of high brightness light source

Under natural convection, you can get more than 1 million Lux illumination

Advanced version of the copy stand design